Introduction:

Cooling towers are iconic structures often seen towering over industrial complexes and power plants, serving a crucial function in maintaining optimal operating temperatures for various industrial processes. While they might seem like mere architectural قیمت برج خنک کننده, these towers play a pivotal role in energy efficiency, environmental sustainability, and overall operational stability. This article delves into the mechanics, applications, and environmental impact of cooling towers.

Understanding Cooling Towers:

Cooling towers are heat rejection devices that facilitate the transfer of excess heat from industrial processes to the atmosphere. They operate on the principle of evaporative cooling, where hot water is circulated through the tower, allowing a small portion of it to evaporate, thereby dissipating heat and lowering the overall temperature of the water.

Mechanism and Components:

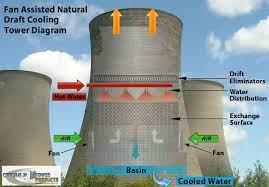

Cooling towers consist of several key components, including a basin to collect hot water, a distribution system to evenly distribute water over the tower’s fill material, fill material (often made of plastic or wood) to increase the surface area for maximum evaporation, fans or natural draft to facilitate airflow, and a drift eliminator to prevent water droplets from escaping into the atmosphere.

Types of Cooling Towers:

Cooling towers can be classified into various types based on their design and operating principles. The two primary classifications are:

- Mechanical Draft Cooling Towers: These towers use fans to create airflow within the tower, drawing air over the water-filled fill material to facilitate evaporation. They are further categorized into induced draft and forced draft cooling towers, depending on the arrangement of fans.

- Natural Draft Cooling Towers: Unlike mechanical draft towers, natural draft cooling towers rely on the stack effect to induce airflow. As warm air rises, it draws cooler air from the surroundings, creating a natural circulation pattern within the tower.

Applications and Importance:

Cooling towers find widespread applications across industries such as power generation, chemical processing, oil refineries, HVAC systems, and manufacturing. They are integral to maintaining optimal operating temperatures for equipment and processes, ensuring efficiency and reliability. In power plants, for instance, cooling towers play a critical role in condensing steam from turbines, allowing for continuous power generation.

Environmental Impact and Sustainability:

While cooling towers are essential for industrial operations, they also pose environmental challenges, primarily related to water consumption and the release of warm, moist air into the atmosphere. However, advancements in technology have led to the development of more sustainable cooling tower designs and practices.

One such advancement is the integration of water-saving measures such as water recycling and the use of alternative cooling fluids. Additionally, hybrid cooling systems, which combine the efficiency of evaporative cooling with other heat rejection methods, are gaining popularity for their reduced water usage and environmental footprint.

Conclusion:

Cooling towers are indispensable components of industrial infrastructure, facilitating heat dissipation and maintaining optimal operating conditions for various processes. While they have traditionally been associated with high water consumption and environmental impact, ongoing efforts towards sustainability and innovation are transforming the way cooling towers operate. As industries continue to prioritize environmental stewardship and resource efficiency, the role of cooling towers in achieving these goals will only become more pronounced.